Spray foam insulation has become a preferred option in new residential and commercial construction due to its performance across energy efficiency, air sealing, and long-term cost control. Compared to traditional insulation materials, it offers a higher R-value per inch, better moisture resistance, and fewer gaps or seams. Builders and architects increasingly specify spray foam in new projects to meet tighter energy codes and long-term durability requirements.

This article outlines the key reasons spray foam is often chosen for new builds, supported by technical specifications, comparison tables, and decision-making guidance. Whether planning a home, multifamily unit, or industrial space, knowing how spray foam fits into modern construction helps with smarter, code-aligned design.

Key Benefits for New Construction

Higher Efficiency and Airtightness

Spray foam creates an air barrier and insulation layer in one step. This dual function reduces thermal bridging and uncontrolled air leaks—critical in new homes built to meet stricter codes.

Long-Term Stability

It adheres directly to framing, sheathing, or subflooring, reducing settling or sagging over time. This helps preserve energy performance for decades with minimal maintenance.

Comparison With Other Insulation Materials

Feature | Spray Foam (Closed Cell) | Spray Foam (Open Cell) | Fiberglass Batt | Cellulose Blown-In |

|---|---|---|---|---|

R-Value per Inch | 6.0–7.0 | 3.5–4.0 | 2.9–3.8 | 3.2–3.8 |

Air Sealing Capability | Excellent | Good | Poor | Moderate |

Moisture Resistance | High | Low | Low | Moderate |

Installation Method | Sprayed in place | Sprayed in place | Cut and fitted | Blown in |

Settling Over Time | None | Minimal | Can sag | Can settle |

Sound Dampening | Moderate | High | Low | Moderate |

Material Lifespan | 30–50 years | 20–30 years | 10–25 years | 20–30 years |

Upfront Cost | High | Medium | Low | Medium |

Bonus Tip: Closed cell spray foam adds structural strength, which can benefit hurricane-prone or high-wind regions.

Technical Specifications

Property | Closed Cell Spray Foam | Open Cell Spray Foam |

|---|---|---|

Density | ~2.0 lbs/ft³ | ~0.5 lbs/ft³ |

R-Value (per inch) | 6.5 | 3.7 |

Air Impermeability | 0.02 L/s-m² | 0.05 L/s-m² |

Water Vapor Permeability | Low (acts as a vapor retarder) | High (not a vapor barrier) |

Flame Spread Index (ASTM E84) | ≤25 | ≤25 |

Application Temperature Range | 40°F to 120°F | 60°F to 120°F |

Cure Time | 24 hours | 24 hours |

Things to Consider Before Making a Decision

- Climate Zone Requirements: Local codes influence the required R-value and whether vapor barriers are needed.

- Wall and Roof Design: Foam thickness must align with cavity depth and thermal goals.

- Project Budget: Spray foam has a higher initial cost but may lower HVAC sizing and operating costs.

- Access During Construction: Spray foam should be installed after the rough-in but before the drywall. Ensure the timing fits the schedule.

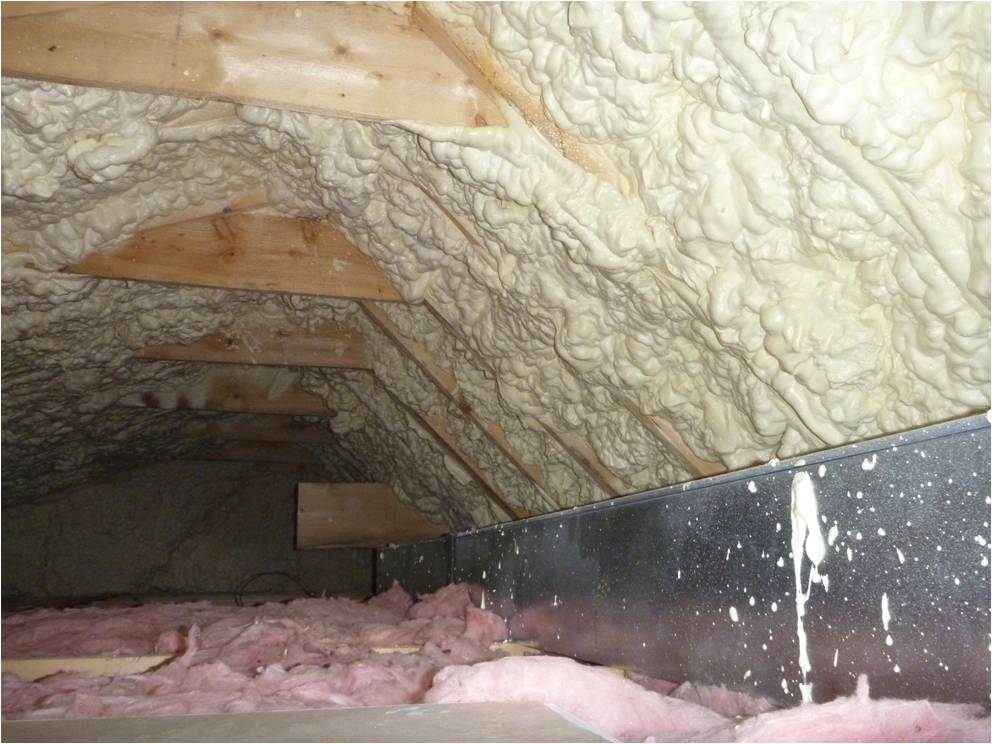

- Building Type: Closed cell is often chosen for basements or crawl spaces where moisture resistance is important, while open cell works well in interior walls and attics.

Bonus Tip: Consult your HVAC contractor before finalizing insulation. Spray foam often requires smaller, more efficient HVAC systems.

Market Data and Performance Outcomes

Recent studies by the U.S. Department of Energy show that spray foam can reduce air leakage by up to 70% in newly constructed homes. This directly affects heating and cooling loads, leading to 15–20% energy savings annually when compared to homes using fiberglass batt insulation.

In regions such as Denver County, where temperature swings are extreme, these energy savings contribute significantly to ROI within 5–7 years of construction.

Common Questions

Does spray foam off-gas harmful chemicals after installation?

Once cured, spray foam is inert. Off-gassing occurs only during application, which is why installers use protective gear and ventilation.

Can it be used in combination with other insulation types?

Yes. Hybrid approaches (e.g., foam board + fiberglass) are common in areas needing specific moisture or fire code compliance.

How long does installation take in a new build?

Installation for an average-size home takes 1–2 days, depending on the number of surfaces and total square footage.

Will it void roofing or siding warranties?

It depends on the manufacturer. Check compatibility with roofing and wall cladding systems before application.

Make the Right Decision

Spray foam insulation offers a blend of energy efficiency, long-term performance, and moisture control that suits the demands of modern construction. For new builds aiming to meet strict energy codes or green certification, it delivers value through tight seals and consistent thermal resistance. Before committing, assess the specific design needs, climate factors, and long-term cost expectations. This ensures you choose the insulation method that meets both code and comfort for years ahead.

Why Spray Foam Is a Top Choice for New Builds FAQ

How does spray foam help with energy efficiency?

It seals air leaks and offers high R-value per inch, reducing heat loss and HVAC load.

Is spray foam safe for residential homes?

Yes. Once cured, it's stable and non-toxic. Professional installation avoids risks during application.

Can spray foam be used in all areas of a home?

Yes. It works for attics, walls, crawl spaces, basements, and floors when matched with the right type (open vs. closed cell).

What’s the difference between open and closed-cell spray foam?

Closed cell has higher R-value, better moisture resistance, and is denser. Open cell is lighter and better for sound dampening.

Does it need maintenance over time?

No routine maintenance is required once installed and protected by drywall or other barriers.

Reviewer: Grace Walker has been in the spray foam business for 9 years and provided suggestions that helped refine this article’s focus on brand development and simple, consistent marketing efforts.