Industrial biotechnology can lead to new routes and potentially to more sustainable production of numerous chemicals. We review the potential of biobased routes from sugars to the large volume commodity, methacrylic acid price, involving fermentation based bioprocesses. We cover the key progress over the past decade on direct and indirect fermentation based routes to methacrylic acid including both academic as well as patent literature. Finally, we take a critical look at the potential of biobased routes to methacrylic acid price in comparison with both incumbent as well as newer greener petrochemical based processes.

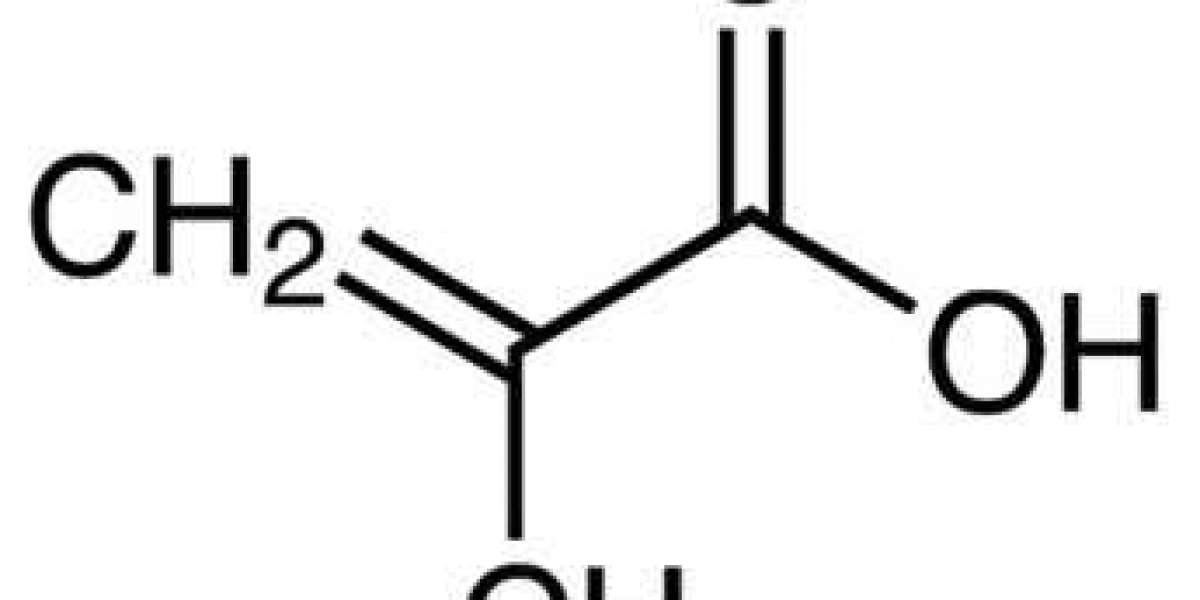

Methacrylic acid (MA) and its ester (methyl methacrylate, MMA) are primarily polymerized into polymethylmethacrylate (PMMA) which is used in the production of acrylic glass. Acrylic glass is used in components of electronics, automobile parts, lights, signs, and displays. Notably, PMMA has a high biocompatibility and low acute toxicity enabling use in medical applications. MMA pricing ranges from $1.75 to $2.25 /kg2,3,4 with an annual market that will exceed $8 billion USD by 2025, growing at a rate of 8–9% per year. This increasing demand for MA is not only due to increased demand for acrylic glass, but also the increasing number of new applications for MMA. MMA will continue to be a critical monomer in the future with currently no equivalent replacement. As demand will continue to grow, more sustainable methods of production need to be considered. Numerous efforts have been made to increase sustainability and reduce waste in petrochemical processes. Recent advances in chemical processes have enabled alternative petrochemical feedstocks and reduced waste. Additionally, the International Energy Agency in 2012 designated MA as a suitable target for the design of a bio-based process.

Direct Production of Methacrylic Acid Price

As illustrated in Figure 1H, there is a direct route from glucose to MA. The biochemical steps involved are primarily derived from valine catabolism, via the natural intermediate methacrylyl-CoA. In valine catabolism, methacrylyl-CoA is hydrated to 3-hydroxyisobutyryl-CoA, hydrolysed to 3-hydroxyisobutyrate and subsequently oxidized to methylmalonate semialdehyde, which enters central metabolism through another oxidation to propionyl-CoA. Bypassing the later steps of valine degradation by expression of a CoA hydrolase/thioesterase with engineered activity on methacrylyl-CoA, can lead to the direct production of MA. Numerous enzymes have been proposed to perform the conversion of methacrylyl-CoA to MA, which may all need to be engineered for this activity. Despite these theoretical descriptions no production has been demonstrated.