Aluminum angles are versatile structural components widely used across industries for construction, fabrication, and engineering applications. Known for their lightweight, corrosion resistance, and durability, aluminum angles are essential in industries such as construction, automotive, aerospace, and manufacturing. Their flexibility in design and adaptability make them a preferred choice for framing, supports, and structural reinforcement. Establishing an aluminum angles manufacturing plant requires an understanding of the production process, sourcing high-quality raw materials, and catering to the growing demand in domestic and global markets.

Understanding Aluminum Angles

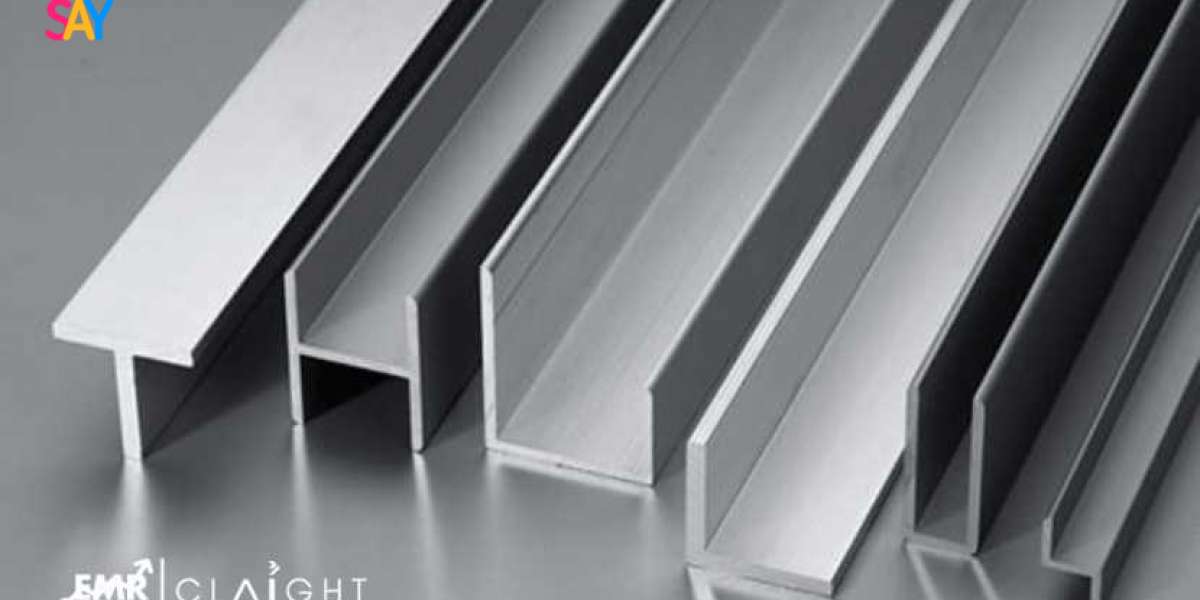

Aluminum angles are L-shaped structural pieces made by extruding or rolling aluminum into precise shapes and sizes. They are available in various dimensions and thicknesses to meet specific industrial requirements. Their lightweight nature, combined with excellent strength-to-weight ratio and corrosion resistance, makes them ideal for use in harsh environments and demanding applications.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/aluminum-angels-manufacturing-plant-project-report/requestsample

Key Benefits and Applications of Aluminum Angles

- Lightweight Strength:

Provide excellent support while keeping structures lightweight. - Corrosion Resistance:

Ideal for outdoor applications due to aluminum’s natural resistance to rust and oxidation. - Versatility:

Used in a wide range of applications, from framing to structural reinforcements. - Ease of Fabrication:

Can be easily cut, drilled, and welded to meet custom requirements. - Recyclability:

Aluminum angles are environmentally friendly and 100% recyclable.

Market Potential and Growth Drivers

The aluminum angles market is expanding rapidly due to the rising demand for lightweight and durable materials in construction and automotive industries. The growing focus on sustainability and recyclable materials has further enhanced their market potential. Additionally, increased infrastructure development in emerging economies and the adoption of aluminum in aerospace and marine industries are key growth drivers, offering significant opportunities for manufacturers.

Steps to Set Up an Aluminum Angles Manufacturing Plant

- Conduct Market Research:

Analyse industry trends, target applications, and competitor offerings to identify opportunities. - Choose a Strategic Location:

Select a site with access to raw materials, skilled labour, and efficient logistics. - Procure Machinery and Equipment:

Invest in extrusion presses, rolling mills, cutting machines, and quality control tools. - Source High-Quality Aluminum:

Partner with reliable suppliers for raw aluminum billets or ingots. - Hire and Train Workforce:

Employ skilled personnel and provide training in manufacturing techniques and quality assurance. - Develop a Production Workflow:

Establish a streamlined process for extrusion, finishing, and packaging. - Implement Quality Control Measures:

Ensure compliance with industry standards through rigorous testing protocols. - Create a Marketing Strategy:

Promote the product through trade fairs, partnerships, and digital platforms to reach target customers.

Manufacturing Process of Aluminum Angles

- Raw Material Preparation:

Aluminum billets or ingots are sourced, inspected, and prepared for processing. - Extrusion:

The aluminum is heated and forced through a die to achieve the desired angle shape. - Cooling and Straightening:

The extruded aluminum is cooled and straightened to maintain precise dimensions. - Cutting and Finishing:

The angles are cut to specified lengths and finished to enhance surface quality. - Quality Testing:

Each angle is tested for strength, dimensions, and corrosion resistance to meet industry standards. - Packaging and Labelling:

The final product is securely packed and labelled for transport and distribution.

Raw Materials Required

- Aluminum Billets or Ingots: The primary raw material for manufacturing.

- Lubricants and Coolants: Used during the extrusion process for smooth operation.

- Packaging Materials: Includes protective wraps and labelling for safe storage and transport.

These materials are sourced from reliable suppliers to ensure consistency and quality in production.

Applications of Aluminum Angles

- Construction:

Used for framing, structural reinforcements, and roofing supports. - Automotive Industry:

Incorporated into vehicle frames, supports, and brackets. - Aerospace and Marine:

Essential for lightweight and corrosion-resistant components. - Manufacturing:

Used in machinery, tools, and equipment for various industrial processes. - DIY and Home Improvement:

Popular in shelving, brackets, and custom furniture projects.

Challenges and Opportunities

Challenges:

- Managing fluctuating raw material prices.

- Meeting stringent quality standards and certifications.

- Navigating competition from alternative materials and established manufacturers.

Opportunities:

- Growing demand for lightweight materials in the automotive and aerospace industries.

- Expanding applications in infrastructure development and renewable energy projects.

- Potential for innovation in custom designs and eco-friendly manufacturing processes.

Future Prospects in the Market

Aluminum angles are poised for steady growth as industries increasingly adopt lightweight and sustainable materials. By focusing on innovation, quality, and customer-centric solutions, manufacturers can leverage the expanding market demand and establish a strong presence in the global aluminum products industry.