Introduction

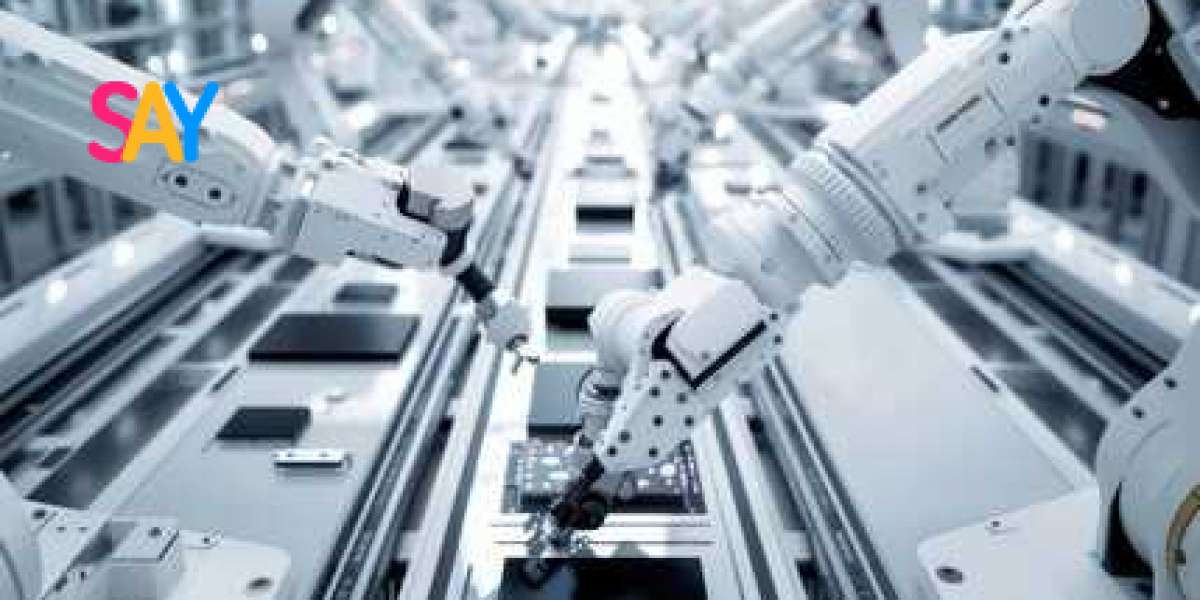

Factory automation companies are revolutionizing manufacturing by integrating cutting-edge technologies that streamline production processes. By leveraging automation, creators can further develop proficiency, decrease operational costs, and increase output. This article jumps into how factory automation companies are driving innovation and transforming production lines across industries.

Outline

Introduction

Outline of how automation streamlines production

Meaning of innovation in factory automation

Background

Improvement of factory automation technologies

Key technologies used to streamline production

Key Innovations in Factory Automation

Undeniable level robotics and AI integration

Internet of Things (IoT) for continuous monitoring

Judicious maintenance and machine learning

Versatile manufacturing systems and high-level twins

Top Factory Automation Companies Leading Innovation

Siemens

ABB

FANUC

Schneider Electric

Rockwell Automation

Conclusion

The destiny of factory automation

Why continuous innovation is indispensable to relentless manufacturing

FAQs

How do automation companies streamline production?

What industries benefit most from automation innovations?

What are the main benefits of factory automation technologies?

How could an association anytime execute advanced automation?

What is the role of AI in present day factory automation?

Background

The advancement of factory automation began with straightforward mechanization and has advanced to include astoundingly complicated, interconnected systems. Today, automation companies are deploying technologies like AI, robotics, and IoT to ensure that manufacturing processes are useful, versatile, and flexible. These innovations diminish human intervention, minimize mistakes, and lay out an information driven manufacturing environment that works on each step of production.

Key Innovations in Factory Automation

Significant level Robotics and AI Integration

Influence: Current robotics, redesigned by AI, can perform complex tasks with exactness and speed. These robots work near human administrators in agreeable circumstances, improving output without compromising security or quality.

Internet of Things (IoT) for Steady Monitoring

Influence: IoT enables consistent monitoring of machinery and production lines. Sensors gather information on execution, which is investigated to update processes, expect anticipated failures, and change exercises to fulfill need changes.

Perceptive Maintenance and Machine Learning

Influence: Using machine learning computations, automation systems can anticipate gear misfires before they occur, ensuring helpful maintenance. This decreases unconstrained extra energy and increases the future of machinery.

Versatile Manufacturing Systems and Mechanized Twins

Influence: Mechanized twins, virtual models of genuine systems, grant creators to emulate and streamline production preceding implementing changes. This innovation gives flexibility in reconfiguring production lines for new things or work processes.

Top Factory Automation Companies Leading Innovation

Siemens

Outline: Siemens is a harbinger in mechanized automation solutions, providing systems that integrate IoT, AI, and cloud computing to streamline production. Their Electronic Undertaking stage assists manufacturers with creating savvy, successful industrial offices.

ABB

Outline: ABB bases mechanical automation and AI-driven solutions, especially in industries like auto, contraptions, and arranged tasks. Their innovations update exactness, speed, and wellbeing in manufacturing conditions.

FANUC

Outline: FANUC is eminent for industrial robotics and CNC systems update complex manufacturing processes. Their robots are intended to conform to various tasks, improving production viability across industries.

Schneider Electric

Outline: Schneider Electric's EcoStruxure stage integrates IoT and automation to convey energy-proficient and sustainable production solutions, helping creators achieve higher output with lower asset use.

Rockwell Automation

Outline: Rockwell Automation offers advanced control systems that further develop production adequacy. Their FactoryTalk software combines ongoing information examination and machine learning to streamline manufacturing cycles and increase throughput.

Conclusion

Factory automation companies like Siemens, ABB, and FANUC are at the bleeding edge of streamlining production through innovative technologies. As automation continues to create, creators who embrace these movements will remain serious, reducing costs and increasing output while maintaining flexibility. Continuous innovation is major in this fast-paced industrial landscape, ensuring creators can conform to changing business area demands with agility.

FAQs

How do automation companies streamline production?

Automation companies streamline production by integrating robotics, IoT, AI, and perceptive maintenance technologies to redesign efficiency, decrease bumbles, and increase throughput.

What industries benefit most from automation innovations?

Industries such as auto, hardware, medicates, and arranged tasks benefit basically from automation, as these areas require high precision, speed, and efficiency.

What are the main benefits of factory automation technologies?

The key benefits include increased production speed, further developed exactness, decreased margin time through perceptive maintenance, and the ability to quickly change in accordance with new things or cycles.

How might an association, at any time at any point, execute advanced automation?

Companies can execute advanced automation by partnering with leading automation providers, assessing their production needs, and integrating versatile technologies like AI-driven robotics, IoT sensors, and steady information systems.

What is the role of AI in present day factory automation?

AI assumes a basic part in present day factory automation by enabling machines to gain from information, seek after ongoing decisions, and further develop processes for most outrageous viability, precision, and output.