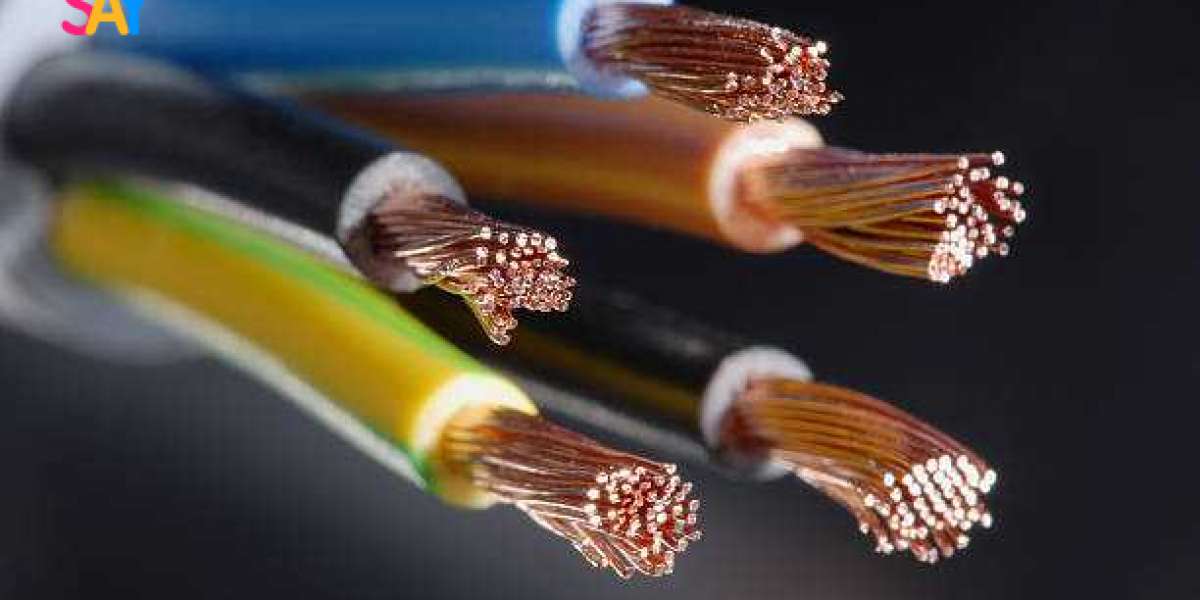

What is an Insulation Line for Power Cables?

An insulation line for power cables is a sophisticated piece of machinery used to apply insulating materials to electrical cables. The process typically involves several stages, including extrusion of the insulation material, curing or cross-linking, and cooling. These lines are essential for producing cables that meet high standards of electrical safety and performance.

Key Features of Insulation Lines for Power Cables

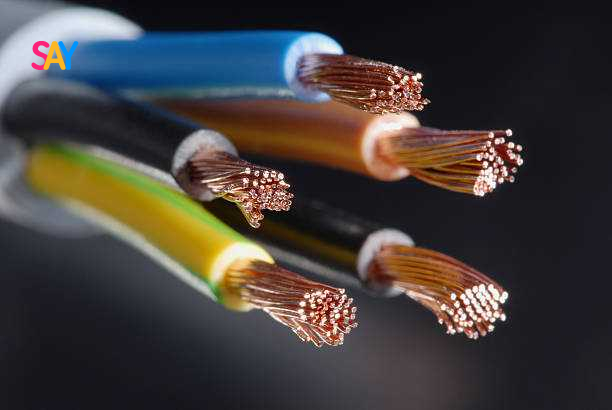

Advanced Extrusion Technology: Modern insulation lines use advanced extrusion technology to apply insulation materials like XLPE (cross-linked polyethylene) or EPR (ethylene propylene rubber) with precision. This ensures a uniform coating that meets the required thickness and consistency.

Curing Systems: The curing process is critical for achieving the desired electrical properties and mechanical strength of the insulation. Insulation lines often include sophisticated curing systems, such as continuous vulcanization or dry cure systems, to ensure optimal performance.

Cooling and Handling: After the insulation is applied and cured, the cables are cooled to solidify the insulation and make the cables ready for further processing. Insulation lines incorporate efficient cooling systems and handling mechanisms to manage the post-insulation process.

Quality Control: To ensure that the insulation meets industry standards, these lines are equipped with advanced quality control systems. These systems monitor various parameters, such as insulation thickness and surface quality, to detect any deviations and maintain high production standards.

Benefits of Using an Insulation Line for Power Cables

Enhanced Safety: Proper insulation is crucial for the safe operation of power cables. Insulation lines ensure that the cables are coated uniformly, reducing the risk of electrical faults and improving safety.

Improved Performance: High-quality insulation enhances the electrical performance of cables, including their resistance to electrical stress and environmental factors. This results in more reliable and efficient power transmission.

Increased Efficiency: Automated insulation lines streamline the production process, reducing manual labor and minimizing errors. This leads to higher production efficiency and lower operational costs.

Flexibility: Modern insulation lines are designed to handle a variety of insulation materials and cable types, providing flexibility to adapt to different manufacturing requirements.

Conclusion

In summary, an insulation line for power cables is an indispensable asset in the cable manufacturing industry. It ensures that cables are insulated with precision and efficiency, meeting the high standards required for safe and reliable electrical systems. By investing in advanced insulation lines, manufacturers can enhance the quality of their products, improve production efficiency, and ultimately deliver superior cables that meet the demands of today’s electrical infrastructure.