In the labyrinthine world of industrial electronics, the march of progress often leaves behind a trail of relics: once cutting-edge equipment now deemed obsolete or malfunctioning. However, amidst the clamor for the latest innovations, lies a industrial electronics repair crucial aspect often overlooked – the art and science of repair. "Reviving Relics: Industrial Electronics Repair Solutions" explores the importance of salvaging and reviving these technological artifacts through skilled repair techniques.

Unveiling the Challenges

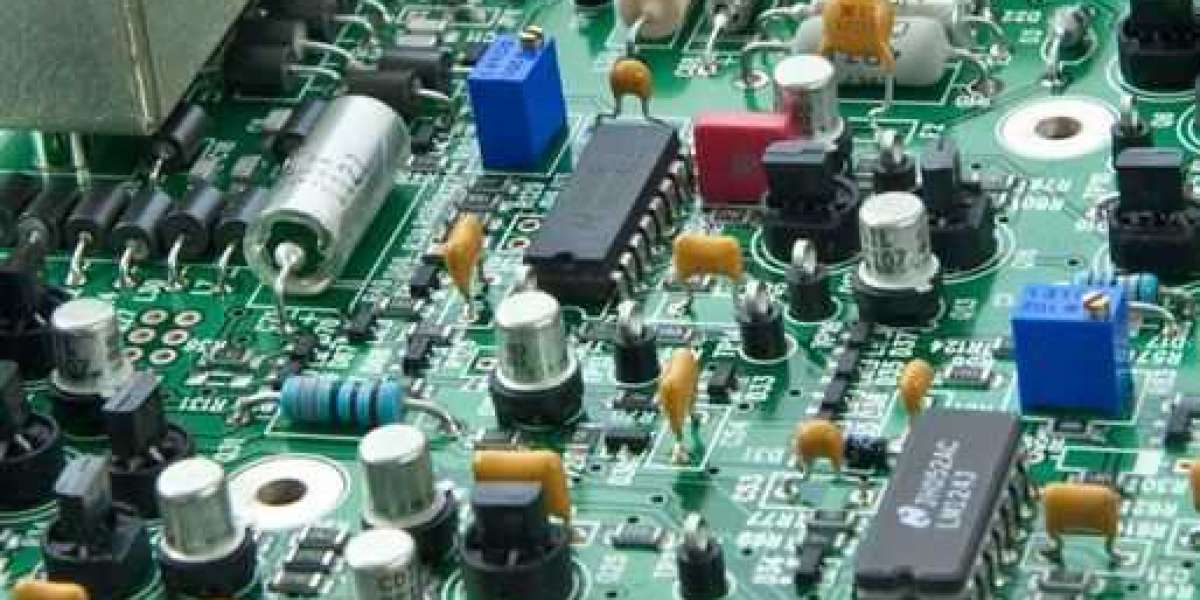

Industrial electronics encompass a vast array of equipment, from power supplies and motor drives to programmable logic controllers (PLCs) and human-machine interfaces (HMIs). Over time, these devices can succumb to wear and tear, component degradation, or even catastrophic failures. The challenge lies not only in identifying the root cause of these issues but also in sourcing compatible replacement parts for outdated models.

The Essence of Expertise

Repairing industrial electronics is no simple feat; it requires a blend of expertise, experience, and intuition. Skilled technicians possess a deep understanding of circuitry, schematics, and troubleshooting methodologies. They can decipher cryptic error codes, trace signal paths, and isolate faulty components with surgical precision. Moreover, they often rely on a vast repository of tacit knowledge accrued over years of hands-on experience.

Navigating Obsolescence

One of the greatest hurdles in industrial electronics repair is navigating the labyrinth of obsolescence. As manufacturers discontinue older models in favor of newer iterations, finding replacement parts can resemble a quest for the Holy Grail. Technicians must scour surplus markets, salvage yards, and specialized vendors in search of compatible components. In some cases, they resort to reverse engineering or custom fabrication to resurrect obsolete parts from the ashes of obsolescence.

The Rise of Retrofits

In an era dominated by rapid technological advancements, retrofitting offers a lifeline for aging industrial equipment. By integrating modern components and interfaces into legacy systems, technicians can breathe new life into antiquated machinery. This not only extends the lifespan of existing assets but also enhances their performance, efficiency, and functionality. Moreover, retrofitting mitigates the risks associated with complete overhauls or replacements, offering a cost-effective alternative for budget-conscious enterprises.

A Sustainable Approach

Beyond the realm of pragmatism lies a deeper ethos – the pursuit of sustainability. In a world grappling with environmental crises and resource depletion, the ethos of repair embodies a profound commitment to conservation and stewardship. By salvaging and refurbishing existing electronics, technicians minimize the ecological footprint of industrial operations, reducing waste and mitigating the demand for new raw materials.

Conclusion

"Reviving Relics: Industrial Electronics Repair Solutions" illuminates the indomitable spirit of innovation that permeates the realm of repair. In the face of obsolescence and adversity, skilled technicians stand as custodians of technological industrial electronics repair heritage, breathing new life into relics deemed unworthy of the scrap heap. Their expertise transcends mere mechanics, embodying a timeless ethos of resilience, resourcefulness, and reverence for the past.

Follow Us More Links:-

Follow Us On Facebook:- https://www.facebook.com/synchronics

Follow Us On Instagram:- https://www.instagram.com/synchronicselectronics/

Follow Us On Twitter:- https://x.com/synchronics

Follow Us On Linkedin:- https://in.linkedin.com/company/synchronics

Address:- 4th Floor, Lotus Enora, Opp. Rutu Villa Bunglows, 24 Mt. Main Road, New Alkapuri, Gotri, Vadodara 390 021, Gujarat (INDIA)

Call Us:- +91-704-308-4455 || +91-704-309-4455 || +91-265-400-1555 || +91-265-356-1183

Email Us:- [email protected]