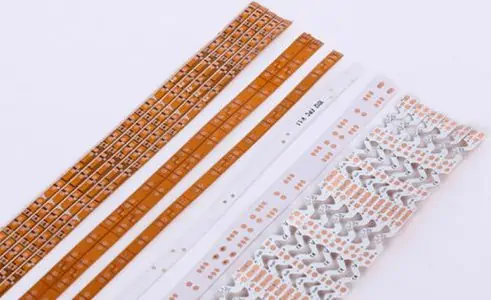

LED strip lights consist of several components, including LEDs, FPCB (flexible printed circuit board), resistors, and other components. LED strip lights are manufactured using a process called surface-mount technology (SMT) assembly, which involves mounting LEDs, resistors, and other components onto the circuit board.

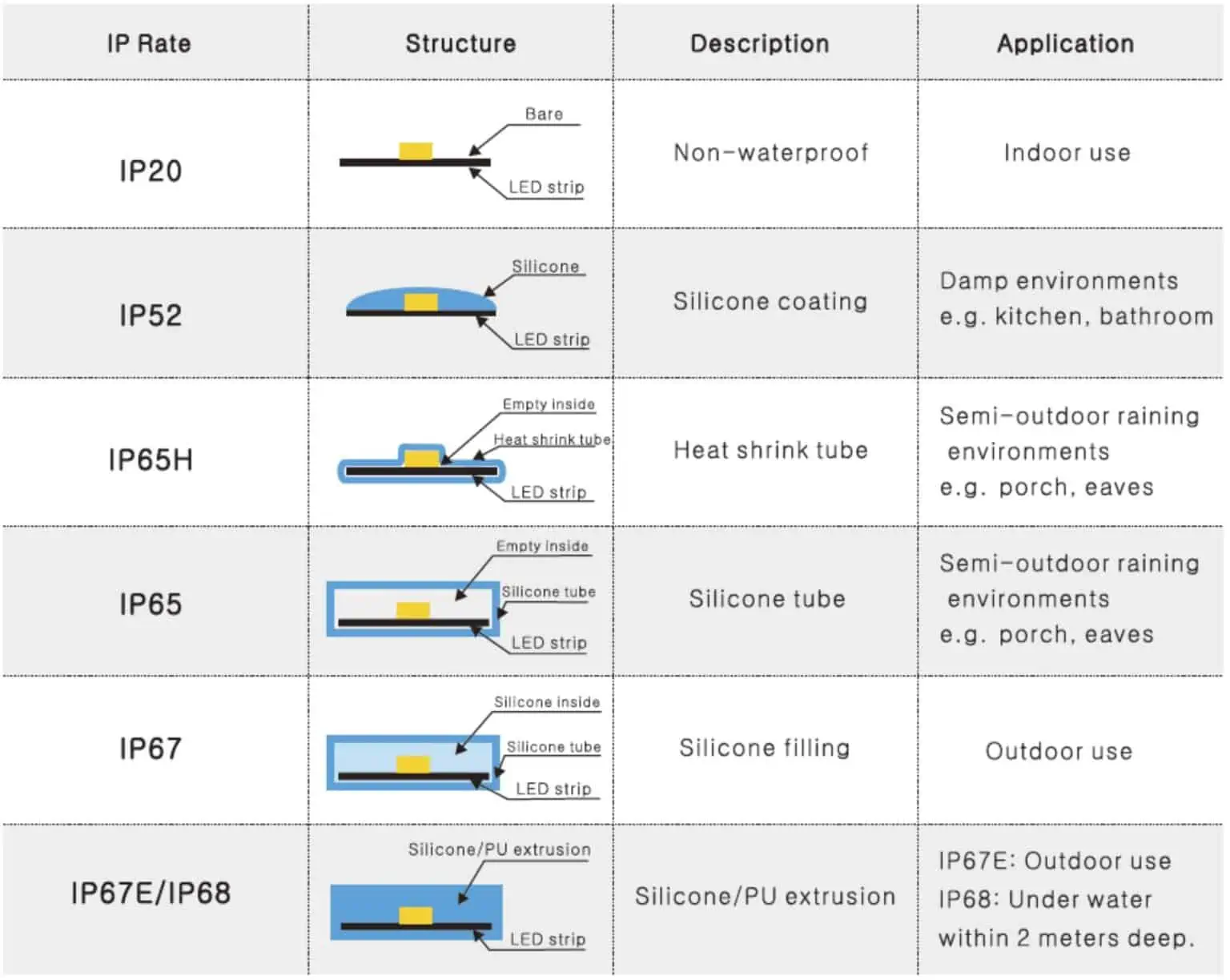

Some outdoor or underwater low voltage light strip are encased in silicone or PU for added protection.

It’s important to note that LED strip lights with higher IP ratings generally have a shorter lifespan compared to IP20-rated LED strip lights because high-rated IP strip lights have limited heat dissipation. In general, LED lights have higher light output in cooler environments. As the temperature rises, the light output decreases. You can see how LED lights are affected by temperature in the chart below.

The most important component of LED strip lights is the SMD LED. The lifespan of the SMD LED essentially determines the lifespan of the LED strip lights. So, how do you calculate the lifespan of LED lights?

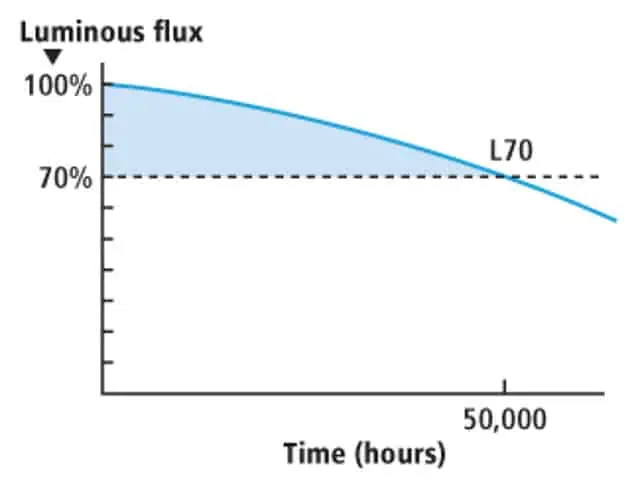

Unlike incandescent or fluorescent bulbs, LEDs gradually dim over time. Unless there is a catastrophic failure due to voltage surge or mechanical damage, LED strip lights can be expected to operate until they are considered too dim.

But what does “too dim to use” mean? Different lighting applications have different answers. However, the industry has somewhat arbitrarily decided that a loss of 30% or 70% of the remaining light output should be the standard. This is referred to as the L70 index and is defined as the time it takes for an LED light to decrease to 70% of its initial light output.

Sometimes, you may see a notation like LxByCz (h) to describe the lifespan of LED lights.

It means the number of hours after which:

- Lumen output has decreased by x percent

- y percent of the lights in the same batch have decreased below the specified lumen output

- z percent of the lights in the same batch have experienced a complete LED failure

For example: L70B10C0.1 (50,000h)

After 50,000 hours, the mentioned LED lights are still providing:

- At least 70% of the initial light output

- 10% of the lights are allowed to provide less than 70% of the initial light output

- And 0.1% of the lights in the batch have failed completely

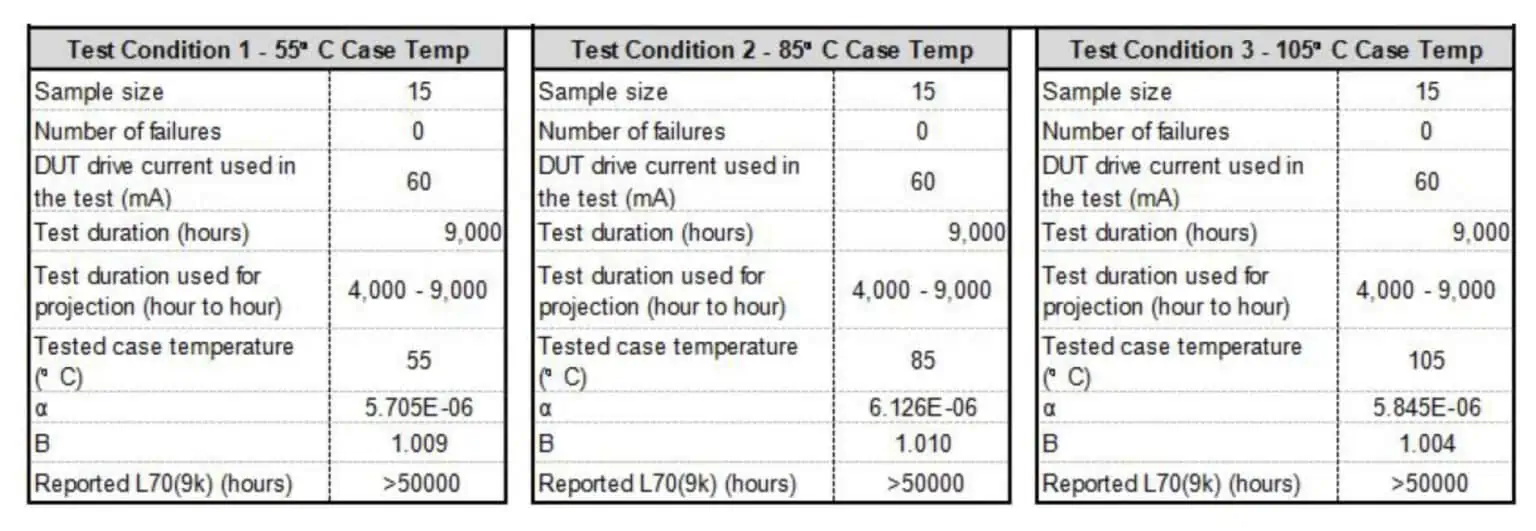

Since the choice of LED materials varies widely between types and manufacturers, a test method called LM-80 has been developed to establish the main standard for LED lifespan testing. LM-80 specifies that the sample is tested at a predetermined temperature and current. The duration to measure the change in light output is 1000 hours, with a maximum of 10,000 hours.

LM-80 testing is generally conducted in a third-party laboratory to ensure objective results, and the findings are reported in a standardized format. All reputable manufacturers perform this test for their LED lights, and reputable LED strip light suppliers can provide LM-80 test reports, especially when purchasing in bulk.

The difficulty with testing the lifespan of LED lights is that it takes a significant amount of time. Even if the LED lights operate 24/7, testing 10,000 hours would take approximately 14 months. This is an endless time frame in rapidly developing fields like LED lighting. Conversely, for products that need to meet the requirement of 50,000 hours, nearly six years of testing is required.

For this purpose, the TM-21 extrapolation algorithm is proposed. This algorithm considers the performance of the LM-80 sample during the first few thousand hours and provides an estimated lifespan.

Please check the full LM-80 test report below.

LM-80 test reports usually indicate the lifespan of L70. However, there are times when we need to know the lifespan of L80 or L90. Don’t worry, I have prepared an Excel tool for you. This tool can convert L70 lifespan to L80 or L90.

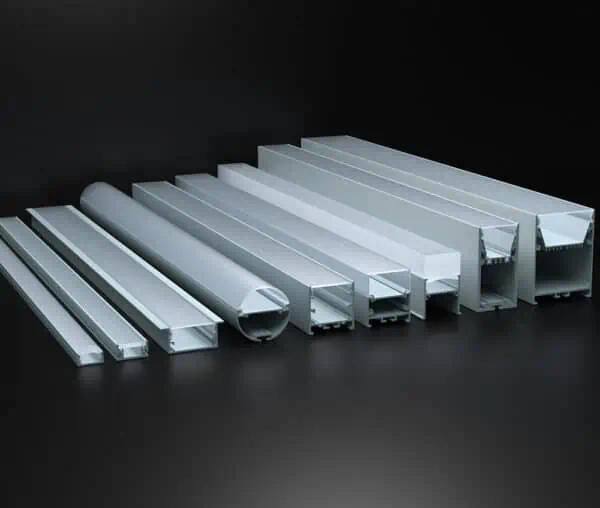

High-quality FPCBs made of pure copper with 2-4 layers ensure smooth current flow, reduce heat generation, and facilitate efficient heat dissipation. Heat can affect the lifespan of LED lights, so it’s important to find ways to dissipate heat. By mounting led low voltage strip lighting on aluminum profiles, we can maximize heat dissipation and reduce operating temperature.

We use 3M VHB tape. However, many suppliers use generic or even counterfeit adhesive tapes. The key is to use high-quality tape for long-lasting installation and heat conduction.

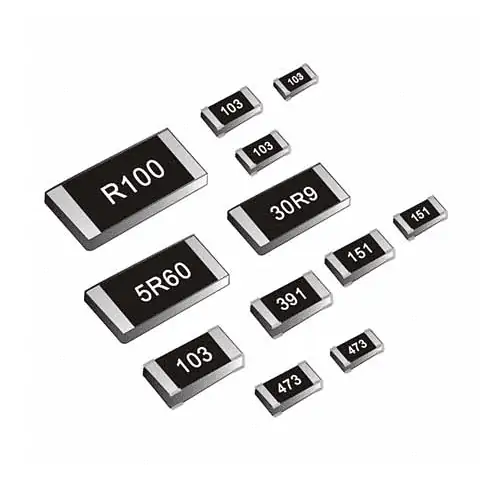

Resistors are used to adjust the forward current through the LEDs to achieve the desired brightness. The value of the resistor may vary among different batches. It’s important to use reputable manufacturers to produce resistors.

Ensure that you use high-quality resistors. Low-quality resistors can decrease the lifespan of LED strip lights or even cause them to fail.

Avoid using LED lights at an excessively high power level. They may appear brighter initially, but they will quickly deteriorate. We know that some of our competitors do this. Excessive heat can also be dangerous when installed on flammable materials.

The power supply is also an important component. You must ensure that you use a branded and high-quality power supply. If the power supply is of poor quality, it may provide unstable voltage, which could exceed the working voltage of the LED lights, causing them to burn out.

And make sure that the power consumption of the LED strip lights does not exceed the rated maximum power of the power supply. To ensure stable operation voltage over a longer period, it’s often recommended that the power consumption of LED strip lights does not exceed 80% of the rated maximum power of the power supply.

Heat significantly shortens the lifespan of LED lights. So when using LED strip lights, we must find ways to dissipate heat effectively. Try to install LED strip lights in well-ventilated areas. LED strip lights mounted on aluminum profile bars are the best option if the budget allows. Aluminum is an excellent heat conductor that can dissipate heat effectively and extend the lifespan of LED strip lights.

The lifespan of LED strip lights in general can reach up to 50,000 hours, but the quality of raw materials such as LEDs, FPCBs, resistors, heat dissipation, and power supply quality will impact the actual lifespan of LED strip lights.

FAQs

1. Q: What is the average lifespan of LED strip lights?

A: LED strip lights have an average lifespan of 50,000 to 100,000 hours of continuous use. This translates to approximately 5.7 to 11.4 years of continuous operation, or significantly longer when used for a few hours per day.

2. Q: How does the lifespan of LED strip lights compare to traditional lighting sources?

A: LED strip lights have a significantly longer lifespan compared to traditional incandescent, fluorescent, or halogen lights. Incandescent bulbs typically last around 1,000 hours, while fluorescents last about 8,000 to 10,000 hours. LED strips outlast both by several times, making them a durable and energy-efficient lighting choice.

3. Q: Can the lifespan of LED strip lights be affected by frequent on-off cycles?

A: LED strip lights are not significantly affected by frequent on-off cycles. Unlike some electronic devices, LED strips are not negatively impacted. Turning them on and off as needed won’t significantly shorten their lifespan.

4. Q: Do LED strip lights lose brightness over time?

A: Like all light sources, LED strip lights gradually experience a decrease in brightness over their lifespan. However, the rate of dimming is much slower than traditional bulbs. Quality LED strips maintain their brightness well over time, providing consistent illumination for years.

5. Q: Can damaged or malfunctioning LEDs be replaced in LED strip lights?

A: In some cases, individual LEDs in LED strip lights can be replaced. However, this task requires technical expertise and soldering skills. For most users, it’s more practical to replace the entire strip if a section of LEDs is damaged or malfunctioning, especially considering the cost and complexity of individual LED replacement.

Raed more: low voltage strip lighting