In the world of semiconductor manufacturing, precision and reliability are paramount. Any deviation from perfection can result in costly defects and delays in production. One crucial component in this process is the ceramic blade probe card, which plays a vital role in the testing of semiconductor wafers. To ensure that these probe cards perform optimally, it's essential to have a proactive maintenance routine in place. We will delve into the intricacies of ceramic blade probe card maintenance, exploring best practices, cleaning techniques, and troubleshooting tips to help you achieve consistent, high-quality results.

What are Ceramic Blade Probe Cards?

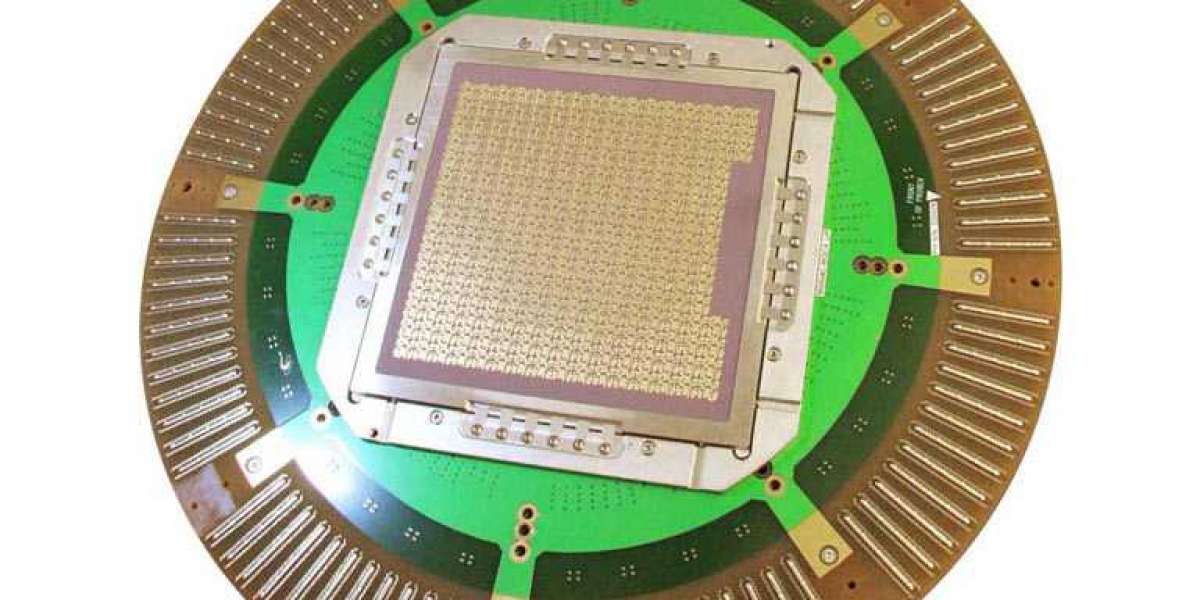

Ceramic blade probe cards are specialized tools used to test semiconductor wafers for defects, ensuring the quality and reliability of the integrated circuits being produced. They consist of a ceramic substrate with an array of tiny, extremely sharp needles (probes) that make contact with the pads on a semiconductor wafer. These probes transmit electrical signals and collect data, allowing manufacturers to detect defects, short circuits, or other irregularities in the wafers.

Significance in Semiconductor Manufacturing:

The accuracy and reliability of probe cards are crucial to the success of semiconductor manufacturing. Any inconsistency in the contact between the probe and the wafer can lead to inaccurate test results, potentially causing defective products to reach the market. Therefore, maintaining Ceramic Blade Probe Cards is not just a routine task; it's a critical aspect of quality control.

Best Practices For Ceramic Blade Probe Card Maintenance:

Maintaining ceramic blade probe cards involves a series of best practices that can help you ensure precision and reliability throughout the testing process.

- Regular Inspection

Start by regularly inspecting your probe cards for signs of wear, damage, or contamination. Pay close attention to the probe tips and the ceramic substrate. Even the tiniest imperfection can affect the accuracy of your testing. If you spot any issues, it's essential to address them promptly.

- Proper Handling

Handle ceramic blade probe cards with care. Avoid any unnecessary pressure or shock that could damage the delicate probes or the ceramic substrate. Using anti-static equipment and wearing proper attire is essential to prevent electrostatic discharge that could harm the cards.

- Calibration

Regularly calibrate your Probe Cards to ensure accurate and consistent test results. Calibration corrects for any deviations or inaccuracies that may have developed over time. It's advisable to follow the manufacturer's recommendations for calibration frequency and procedures.

- Cleaning

Cleaning is one of the most critical aspects of ceramic blade probe card maintenance. Contaminants such as dust, residue, or debris can adversely affect the contact between the probes and the wafer, leading to inaccuracies in testing. Follow these cleaning techniques.

- Storage

Proper storage is crucial to protect ceramic blade probe cards when they are not in use. Store them in a clean, dust-free environment and use protective covers or containers to shield the probe tips from potential damage.

Troubleshooting Tips for Ceramic Blade Probe Cards:

Even with regular maintenance, issues with ceramic blade probe cards can arise. It's essential to be prepared to troubleshoot these problems effectively.

- Inconsistent Test Results

If you notice inconsistent test results, the issue may be related to damaged or worn probe tips. Inspect the tips carefully and replace any that appear compromised. Regular calibration can also help identify and rectify inaccuracies.

- Bent or Broken Probes

Bent or broken probes can be a common issue, especially if the probe card has been mishandled. In such cases, replace the damaged probes with new ones to maintain precision during testing.

- Electrostatic Discharge (ESD)

ESD can damage the probe card and wafers during testing. Ensure that your work environment is properly grounded, and use anti-static equipment and attire to prevent ESD.

- Contaminants

If you notice contaminants on the probe card's surface, clean it using the recommended cleaning techniques mentioned earlier. Regular cleaning can prevent this issue.

Conclusion:

Maintaining ceramic blade probe cards is a crucial aspect of ensuring precision and reliability in semiconductor manufacturing. By following best practices, regularly inspecting, calibrating, and properly cleaning your probe cards, you can minimize the risk of inaccuracies and defects in your products. Additionally, knowing how to troubleshoot common issues will help you address problems promptly, preventing costly delays in your production process. Remember, a well-maintained ceramic blade probe card is a key to achieving consistent, high-quality results in semiconductor testing.