In today's fast-changing world, there has never been a greater demand for flexible, robust, and cost-effective solutions. One of these solutions which have become highly sought after in many industries is the HDPE sheet. Renowned for its strength and wide application, Hdpe sheet 2mm are a backbone in construction and packaging industries as well as water management systems.

In case you are keen on knowing what is special about HDPE sheets and how they may benefit various projects, keep reading to discover all that you need to know.

What is an HDPE Sheet?

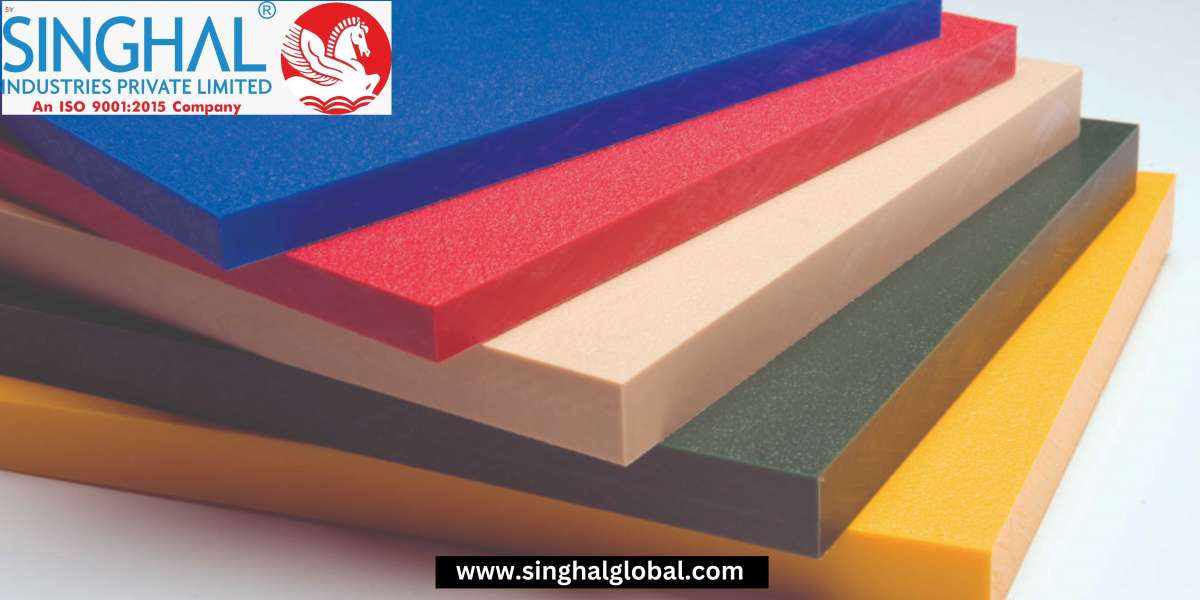

HDPE has a high density-strength ratio and is thus preferred for items that must be strong as well as chemical-resistant. When such material is formed into flat, uniform panels, it becomes what is known as an HDPE sheet.

These are lightweight but highly strong. These are shock-resistant, water-resistant, chemical-resistant, and resistant to UV and thus can be utilized for internal as well as external purposes. Because of all these properties, HDPE sheets have replaced a large number of traditional materials such as wood, metal, and glass in certain applications.

Types of HDPE Sheets Based on Thickness

HDPE sheets also vary in thickness appropriate to specific uses. Thickness determines strength, flexibility, and applicability. Two of the most popular thicknesses that are most often on order are:

HDPE Sheet 2mm

This mid-range thickness sheet is usable in model making, signage, protective wrap, and lightweight structural panels. It is durable to avoid tearing but flexible enough for bending or shaping to some degree.

This thickness also gives excellent resistance to the environment, making it a good fit for outdoor as well as indoor uses. In packaging, agriculture, and automotive sectors, 2mm thickness HDPE sheets provide assured protection cover.

HDPE Sheet 500 Micron

On the other end of the scale, the HDPE sheet 500 micron (or 0.5mm) is essentially a very thin sheet of plastic that's used wherever light weight and flexibility are paramount. This is suitable for protective covers, liners, and moisture barriers.

The Hdpe sheet 500 micron are also widely used as liners in agricultural settings or as an underlay during construction work to prevent seepage of water. Thin as they are, the sheets do not lose their essential chemical resistance and water resistance typical of HDPE.

Fabrication and Processing of HDPE Sheets

Among the benefits of HDPE sheets is that they are simple to fabricate. Unlike some materials, which require specialized equipment or techniques, HDPE sheets may readily be cut, shaped, and assembled with relatively rudimentary equipment. Following is a glimpse of some common fabrication processes:

Cutting and Shaping

HDPE sheet can be cut with basic tools such as saws, routers, or laser cutting machines, based on the thickness. Thin sheets such as HDPE sheet 500 micron have sharp cutting tools generally used for clean edges. Due to the flexibility of HDPE, it can be bent or thermoformed by heat, which enables curved or specially shaped components.

Welding and Joining

Heat welding is a very common technique to weld HDPE sheets, particularly in the case of such applications as water tanks where a seal-leak-proof seal is the bare necessity. Heat welding is carried out by softening the edges of sheets with heat and then pressing them together with pressure to form a seal-less joint. This welding is very strong and avoids fluid leakage, and that is why HDPE sheets are employed for tanks and liners.

Surface Treatment

HDPE sheets are sometimes subjected to surface treatments to enhance adhesion or paintability in certain applications.

Environmental Impact and Sustainability of HDPE Sheets

As the environment comes under more scrutiny, sustainability of materials is a critical factor in choice. HDPE sheets have several environmentally friendly attributes:

Recyclability

After being used, HDPE sheeting can be collected, melted, and reconditioned into new material, reducing landfill waste and conserving raw materials. HDPE's recyclability is why it's a favorite among industries in those markets looking to reduce their carbon footprint.

Chemical Stability and Non-Toxicity

HDPE is not biodegradable and does not readily break down into harmful microplastics and also does not leach toxic chemicals into the environment, which makes it safer for the ecological environment, particularly when applied for water storage or agricultural uses.

Considerations

Although HDPE is strong and can be recycled, it is nonetheless a fossil fuel-based plastic, thus sustainable methods such as recycling and careful disposal are essential to limit its effects on the environment.

Innovative Applications and Emerging Trends in HDPE Sheets

Some of the future trends are:

1. Green Building and Sustainable Architecture

HDPE sheets increasingly find application as vapor barriers and waterproof membranes in green building construction. The chemical resistance and strength help improve building lifespan while enabling green construction methods.

2. Modular and Portable Water Tanks

Usage of HDPE sheets in modular water tanks is on the rise, especially in disaster-prone or remote locations. The sheets are simple to move around and install on-site, providing a ready-to-use water storage option during difficult times.

3. Advanced Agricultural Solutions

Thin sheets of HDPE like type 500 micron are utilized to line irrigation canals to cut down water loss and contamination. They are also utilized to build greenhouses to promote temperature control and moisture retention.

4. Marine and Offshore Applications

With their ability to resist corrosion when in contact with saltwater, Hdpe sheet for water tank are coming to be used more and more in marine areas—dock fenders, boat components, and pipelines buried underwater—where other materials may rapidly deteriorate.

Conclusion

HDPE sheets are a superior material option that packs strength, flexibility, and safety. From heavy-duty HDPE sheet 2mm for structural use, light HDPE sheet 500 micron for protective cover, to custom HDPE sheets for water tanks for safe and watertight storage, this versatile plastic is perfect to meet different industrial and business needs.

Having knowledge about the types, traits, and applications of HDPE sheets can provide you with the authority to make the correct decisions when selecting materials for your projects, achieving maximum efficiency and longevity in your outcomes.

Frequently Asked Questions (FAQs)

Q1: Can HDPE sheets be used for outdoor applications?

Yes, HDPE sheets can be used outdoors, especially when UV-stabilized. HDPE sheets are resistant to impact, chemicals, and moisture, which makes them ideal for outdoor signage, tanks, and protective guards.

Q2: What is the difference between HDPE sheet 2mm and 500 micron?

The key difference is thickness and stiffness. 2mm HDPE sheet is thicker and provides more strength and durability, which is suitable for structural use. The 500 micron (0.5mm) sheet is thinner and provides flexibility and light protection mainly used as liners and damp courses.

Q3: Are HDPE sheets safe for storing drinking water?

Yes, HDPE sheets used in water tanks are typically food-grade and non-toxic. They do not leach and emit dangerous chemicals, so safe to use for storing drinking water.