Introduction

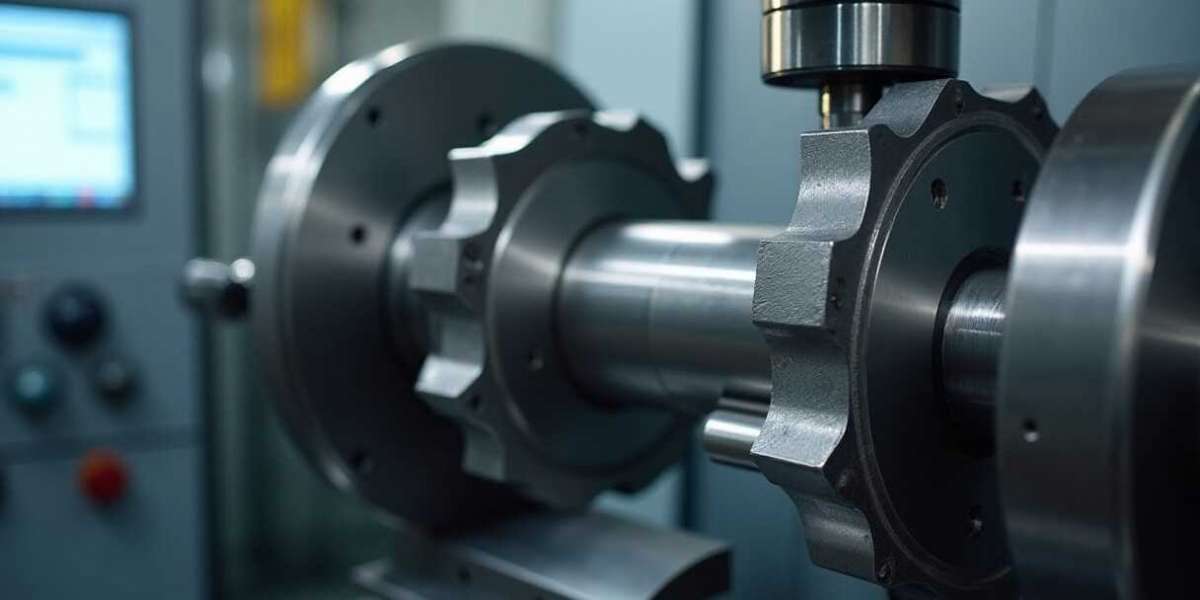

Lathe jaws play a crucial role in machining processes. They hold the workpiece securely in place on the lathe, enabling precise cuts and shaping. Without reliable lathe jaws, the accuracy of machining suffers, leading to poor product quality and wasted materials.

Because of this, choosing a reliable lathe jaws manufacturer is very important. The right manufacturer ensures you get high-quality jaws that fit perfectly and last longer. This blog will guide you step-by-step on how to find the best lathe jaws manufacturer in the US.

Understanding Lathe Jaws

Lathe jaws are parts attached to the lathe chuck. Their job is to grip the workpiece firmly during machining. Without a good grip, the workpiece can slip or move, ruining the final product.

There are different types of lathe jaws:

Standard Jaws: The most common type, used for general work.

Soft Jaws: Made from softer materials that can be machined to custom shapes for special workpieces.

Hard Jaws: Made from hardened steel, durable for heavy-duty machining.

Lathe jaws are used in many industries such as automotive, aerospace, metalworking, and manufacturing. Each industry requires jaws that meet specific quality and design standards to ensure safe and accurate machining.

Importance of Quality in Lathe Jaws

Quality matters a lot when it comes to lathe jaws. High-quality jaws ensure the workpiece stays steady, allowing for precise cuts. Poor-quality jaws may wear out quickly, cause slipping, or damage the workpiece.

How does this affect you?

Machining Precision: Accurate jaws mean better product quality. According to a 2022 industry survey, 75% of manufacturers reported increased defect rates when using low-quality jaws.

Efficiency: Good jaws reduce machine downtime and rework. This can save up to 20% in production costs annually.

Long-term Savings: While high-quality jaws might cost more upfront, they last longer and reduce waste, making them more economical over time.

Key Factors to Consider When Choosing a Manufacturer

Finding a reliable manufacturer means looking beyond just price. Here are some important factors:

Reputation and Experience: Look for manufacturers with a strong track record. Those with 10+ years in the industry usually have refined processes and quality control.

Range of Products: Choose a manufacturer who offers various types of lathe jaws and sizes to meet your needs.

Customization Options: Sometimes you need jaws made to special specifications. A good manufacturer will offer custom machining and design services.

Researching Potential Manufacturers

Start your search using these methods:

Online Resources and Directories: Websites like ThomasNet or industry-specific directories list verified manufacturers.

Reviews and Testimonials: Check customer feedback on Google, LinkedIn, or the manufacturer’s site to learn about product quality and service.

Industry Forums and Groups: Join machining and manufacturing forums on platforms like Reddit or LinkedIn. Members often share recommendations and experiences.

Evaluating Manufacturer Credentials

Before making a decision, check these credentials:

Certifications and Standards: Look for ISO certifications (like ISO 9001), which show the manufacturer meets international quality management standards.

Manufacturing Processes and Technology: Ask about the machinery they use—modern CNC machines and quality control tools are a plus.

Warranties and Guarantees: Reliable manufacturers stand by their products with warranties or satisfaction guarantees, which protect your investment.

Comparing Pricing and Value

Price is important but don’t choose the cheapest option blindly.

Understand the relationship between cost and quality. Low prices might mean lower material or poor craftsmanship.

Request detailed quotes from multiple manufacturers. This should include unit price, shipping, taxes, and any setup fees.

Watch for hidden costs such as extra charges for customization, delivery delays, or poor customer service that might cost you more in the long run.

Communication and Customer Service

Good communication is often a sign of a reliable manufacturer.

Choose companies that respond quickly and clearly to your inquiries.

Evaluate their customer support and after-sales service — are they easy to reach? Do they offer technical advice or support if issues arise?

Building a strong relationship can help ensure smooth orders, timely deliveries, and future custom needs.

Making the Final Decision

After researching and evaluating:

Weigh all information carefully: quality, price, experience, and service.

Trust your instincts based on your interactions with the manufacturer.

Start with a small order to test product quality and service before committing to large purchases.

Conclusion

Choosing a reliable lathe jaws manufacturer in the US is a key step to improving your machining quality and efficiency. By understanding lathe jaws, valuing quality, researching manufacturers carefully, and evaluating their credentials, you can find a partner that meets your needs.

Taking the time to find the right manufacturer pays off in fewer defects, lower costs, and better overall production. Remember, a trusted manufacturing partner is an investment in the long-term success of your business.