Hydraulic systems play a crucial role in industrial machinery, construction equipment, and manufacturing processes. However, contaminated hydraulic oil can lead to equipment failure, increased maintenance costs, and reduced efficiency. This is where hydraulic oil filtration systems come into play. These systems help remove contaminants, ensuring smooth and reliable performance.

What Are Hydraulic Filtration Systems?

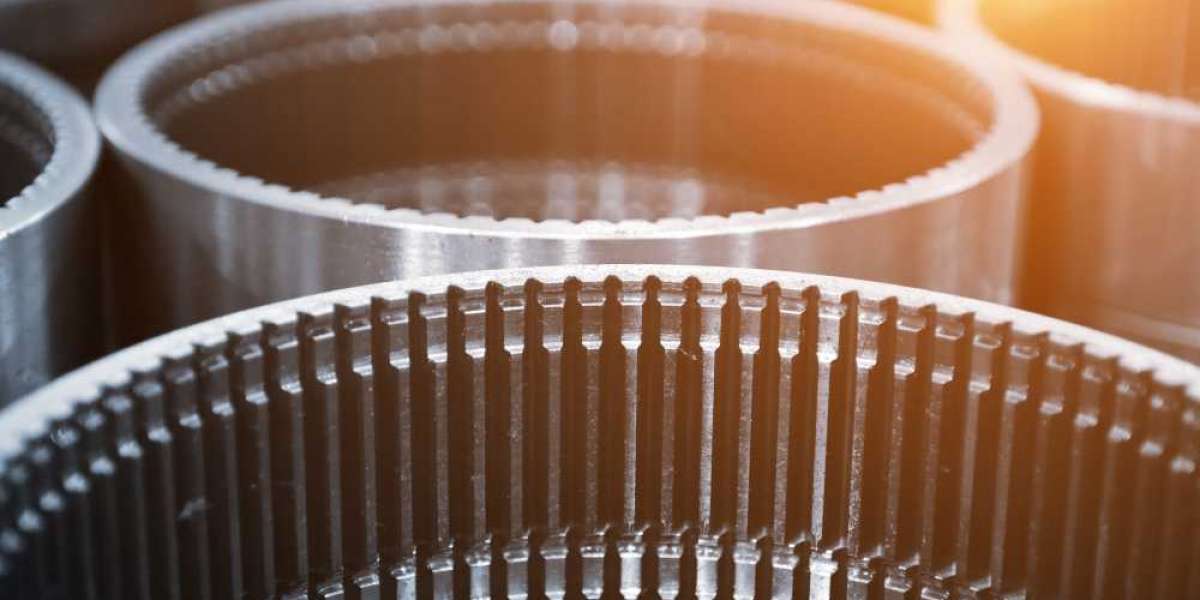

Hydraulic filtration systems are designed to remove dirt, metal particles, and water from hydraulic oil. These contaminants can cause excessive wear and tear on components, leading to system breakdowns. A well-maintained filtration system helps prevent these issues and ensures optimal equipment performance.

Key Components of Hydraulic Filtration Systems

Filter Elements – Capture dirt, metal shavings, and debris.

Pressure Filters – Installed in high-pressure lines to remove contaminants.

Return Line Filters – Clean oil before it returns to the reservoir.

Offline Filtration Units – Work independently to filter oil continuously.

Benefits of Hydraulic Oil Filtration Systems

1. Prolongs Equipment Life

By removing harmful contaminants, hydraulic oil filtration systems extend the lifespan of pumps, valves, and actuators.

2. Reduces Maintenance Costs

Clean oil prevents component wear, reducing the need for frequent repairs and replacements.

3. Improves System Efficiency

Hydraulic equipment operates more efficiently with clean oil, leading to smoother performance and reduced downtime.

4. Prevents System Failures

Contaminated oil can cause overheating and mechanical failures. A reliable hydraulic filtration system minimizes these risks.

Choosing the Right Hydraulic Filtration System

When selecting a hydraulic oil filtration system, consider factors such as:

Filtration Efficiency – Choose a system with a high dirt-holding capacity.

Flow Rate – Ensure the system matches your hydraulic system's oil flow requirements.

Micron Rating – Select filters that can capture fine particles effectively.

Final Thoughts

Investing in a high-quality hydraulic oil filtration system is essential for maintaining machinery efficiency, reducing operational costs, and preventing breakdowns. Regular maintenance and timely filter replacement further enhance the effectiveness of your hydraulic filtration system.

For premium hydraulic filtration solutions, choose a trusted supplier like Harvard Filtration, ensuring long-lasting performance and reliability.